TL;DR – a reefer container is an electric-powered metal container that is used for storing or transporting temperature-sensitive products

What is a reefer container?

The word “reefer” in the container industry reefers to a refrigerated, temperature-controlled container. These are designed to actively maintain chilled or frozen conditions during transportation and storage.

Reefer containers generally have variable temperature control and can handle both sub-zero temperatures and general cooling duties – much as you would find in a fridge-freezer.

However, there are specialist reefer containers with more specific functions, such as ultra-freezers, which are designed to reach extremely low temperatures.

Unlike standard shipping or storage containers (also known as dry containers), reefer containers require a power source. They also have insulation panels that slightly reduce their internal capacity when compared to a similarly sized, non-reefer container.

In this article, we will look at how reefer containers work, the different types currently available and explore how they are used across different industries.

Reefer container vs dry container – at a glance

| Dry container | Reefer container | |

| Power required | No | Yes |

| Variable temperature | Ambient temperature only | Yes |

| Can provide heat (though insulation may be possible) | No | Yes |

| Weight | Heavy | Very heavy |

| Sizes | Usually 5ft – 40ft | Usually 8ft – 40ft |

| Cost | ££ | ££££ |

How does a reefer container work?

Most reefer containers have a refrigeration unit at one end. It uses electricity to drive a vapour-compression refrigeration cycle, in which refrigerant is compressed, condensed into a high-pressure liquid, then expanded in the evaporator to absorb heat and cool the internal air.

This air is then circulated through the container by high-performance fans that force chilled air from the refrigeration unit through the floor and around the cargo, returning via vents.

In summary, air is:

- Cooled

- Circulated through the container

- Returned to the cooling unit

Just like your fridge, correct stacking of items is important to ensure an even temperature spread throughout the unit. If items are too densely packed, those at the center may not be chilled as efficiently as those at the side.

In most cases, reefers use a 480 Volt, 32 Amp, 3 phase, 4-pin plug – female (missing neutral).

Many containers have the option of remote monitoring, which enables users to check and change the temperature from their phone or laptop. This function is sometimes offered as standard.

Some newer models also offer enhanced efficiencies, boasting high-tech insulation and even solar panels to drive down energy costs.

Reefer container temperature ranges

Standard reefer containers typically maintain temperatures between -13°F and +68°F, though more sophisticated “standard” models have greater temperature ranges. Standard reefers are suitable for most customers with cold storage needs.

Some of the specialist reefer containers available include:

- Ultra-freezers – which can take temperatures down to as low as -103°F.

- Blast freezers – which typically use multiple cooling fans to chill air more rapidly than standard reefers.

Also loosely fitting the reefer category are heated containers, which are sometimes used by bakeries during the proving process or as large industrial dryers. They can also be used to test automotive or other components at high temperatures.

With minimum temperatures often as low as -40°F, standard reefer containers meet most commercial freezing needs. Among the many food items that can safely be stored are:

- Ice Cream

- Meats and poultry

- Frozen ready meals

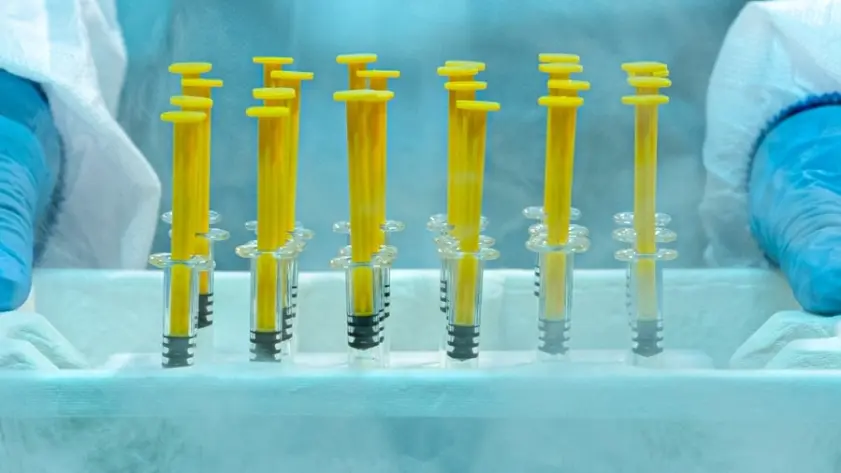

Many vaccines and pharmaceutical products can also be stored at these temperatures.

Among the items that benefit from even colder storage – as seen in an ultra-freezer – are oily fish, such as bluefin tuna, and some kinds of vaccines, including the Pfizer-BioNTech COVID-19 vaccine.

Chilled, not frozen

Often, however, reefer containers provide only a light chilling. This is sufficient to help preserve products such as bacon, lettuce and fresh milk. Temperature ranges for these and similar products can vary, but most chilled goods are kept between 32°F and 40°F.

As most modern reefer containers lean on years of refrigeration technology, they are highly dependable when it comes to temperature precision.

With fans to ensure cold air circulation, deviations from your required temperature are uncommon. Many systems have alarms that sound if fluctuations exceed normal thresholds of one or two degrees.

Products best suited to different cold storage temperature ranges

| Chilled range 32°F+ | Frozen range (32°F to -40°F)

|

Ultra-low range (lower than -40°F)

|

| Lettuce and salads | Ice cream | Some vaccines and biologics |

| Dairy goods | Frozen seafood | Frozen plasma / blood products |

| Fresh meat | Frozen meats | High-value seafood such as tuna |

| Fruits | Frozen vegetables | |

| Ready-to-eat meals |

Types of reefer containers

The cold storage industry is vast, with a cold chain that keeps products chilled from the moment they are picked or created to the moment they are sold.

As such, different types of refrigerated storage containers are used across the cold chain.

Shipping reefer containers

These ISO-standard shipping containers are used to transport temperature-sensitive goods such as perishable foods and pharmaceuticals over long distances. Refrigerated shipping containers typically plug directly into the power supply of whatever is transporting them.

This kind of container is also sometimes used to transport chemicals and flowers to prevent spoilage.

Cold storage containers

Many products that need refrigeration spend extended periods in storage before being used.

A pre-washed bag of lettuce, for example, may be packaged in a warehouse, taken to a cold storage container until it is ready for transportation, and then taken to a supermarket holding area where it may be kept until it is ready to go on the shelves.

As a result, there are hundreds of thousands of cold storage containers in use all over the world.

Multi-temperature cold storage containers

A typical cold storage container can only maintain a single temperature throughout the container. However, some innovative solutions allow users to create zones within their container space with different temperatures.

TITAN, for example, has two possibilities for clients with different temperature needs. The Arctic SuperStore is a modular arrangement of standard reefer containers and blast freezers that enable products to be kept at different temperatures.

For those keen to maximize available space, the new Arctic MegaStore from TITAN adds a second story, increasing stacking capacity.

Common uses of reefer containers

Reefer containers are used across multiple sectors, and you will likely use or consume a product stored in one many times a day. They are widely seen in the following sectors:

Food and beverage

Cold storage reefer containers keep everything from fruit and vegetables to poultry and fresh meat in top condition.

Pharmaceuticals and healthcare

Many medicines, vaccines, and blood/plasma products need cold storage – and the market for temperature-sensitive pharmaceutical products is growing dramatically. When errors occur, the consequences can be catastrophic: losses in the pharma sector from cold chain inefficiencies and mistakes are reported to cost around $35 billion a year.

Events, catering and seasonal demand

When organisers of large events such as festivals, concerts and awards shows need catering, they often require a refrigerated container (or several) to be positioned on-site. These keep drinks chilled and ensure any products that need to be kept cold, such as sandwiches or burgers, can be safely stored.

Temporary cold storage units also provide retailers with extra capacity during seasonal demand. Large grocery stores, for example, often need much more cold storage space in the run-up to Christmas.

Logistics and supply chain

In the moments before goods can be transported from A to Z (and every step in between), they often need to be kept in cold storage at a depot or hub. Reefer containers offer a convenient and affordable alternative to permanent cold stores.

Reefer sizes and specifications

The most common sizes for reefer containers are 10 foot, 20 foot and 40 foot. The 20 footer is the most popular, as it is sizable and yet still relatively portable.

The typical internal capacity of these containers is as follows:

- 10ft reefer container – 423 cubic feet

- 20ft reefer container – 988 cubic feet

- 40ft reefer container – 2,400 cubic feet

Their footprints are as follows (all sizes approximate):

- 10ft reefer container – 10ft x 8ft

- 20ft reefer container – 20ft x 8ft

- 40ft reefer container – 40ft x 8ft

At around 80dB, the refrigeration unit of reefer containers produces noise that may exceed permitted levels in some areas. However, this can be reduced significantly with a shielding device known as an acoustic cabin.

Buying vs hiring a reefer container

Unlike dry storage containers, which have no power, reefer containers are sophisticated devices. As a result, their price tag is often in the tens of thousands.

Let’s have a look at some of the latest figures.

How much does a reefer container cost?

If renting a cooling container, ballpark figures per month are as follows:

10ft – $540 to $750

20ft – $780 to $1,080

40ft – $930 to $1,260

Rental contracts tend to be flexible, allowing customers to respond to market forces, and often include maintenance.

Regulations, food safety and compliance

US refrigerated containers used for food storage need to comply with strict FDA Food Code and USDA/FSMA regulations to ensure goods are kept at the correct temperature.

Chilled high-risk foods such as dairy and meat must be kept at temperatures no higher than 41°F.

For HACCP/FSMA compliance, temperature monitoring is required for audits, and relevant information should be kept for 2 years in most cases. Reefer units must also be serviced regularly.

Key things to consider before choosing a reefer container

To help you decide the best path for your business, here are some common considerations when thinking about cold storage solutions:

Rent or buy?

While buying temperature-controlled storage may work out more affordable in the long term, it requires a large capital expenditure up front and ties you to your storage solution. Cold room hire can help with cash flow and is the more agile solution. Many cold storage customers who rent scale up or down as their needs demand.

Temperature range

Most standard cold storage containers operate somewhere in the -40°F and +113°F range, which is sufficient for almost all uses. If you need more extreme temperatures, consider an ultra-freezer, which may be capable of going as low as -103°F.

Unit size

The most common cooling container is the 20 footer, widely available across the US and Canada. However, if you have greater storage needs, a 40 foot reefer may be more appropriate. Or you may wish to enquire about modular, bespoke solutions, which involve several or even dozens of containers arranged in an open-plan formation.

Site location

While containers are portable, they are not easily repositioned once they have been installed on site. As they weigh several tons, it makes sense to carefully consider where they will be needed before asking the reefer company to deliver your containers.

Need a reefer container? Speak to one of our specialists to find the right reefer container for your needs.

See more UK news and blogs

Storage containers and shipping containers are often confused. This quick guide explains the key differences, standards, and what you need to know before renting or buying.

Revolutionary two-storey design, modular flexibility, and huge storage capacity – the Arctic MegaStore redefines cold storage efficiency.

Cold chain failures cost industries billions each year but the true damage goes far beyond product loss. From reputational harm to regulatory penalties, even a single temperature excursion can trigger financial, operational and brand crises.