Despite decades of warnings and improvements in monitoring technology, cold chain breakdowns still cost industries billions.

And the most serious consequences don’t show up on an operations report — they show up in board meetings, shareholder updates, national headlines and social media feeds.

This is bigger than product loss

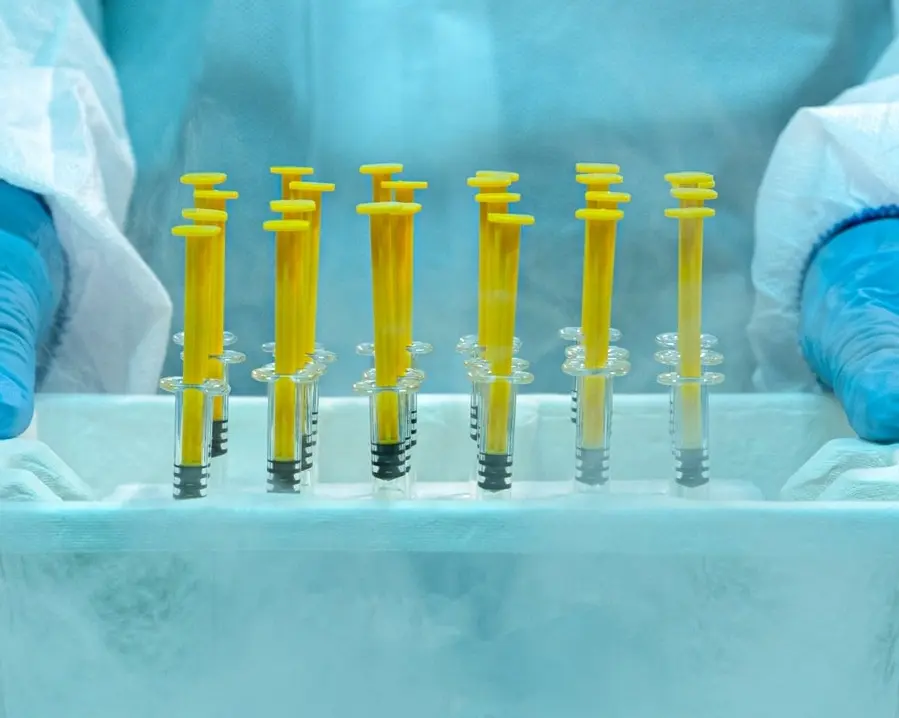

At a surface level, cold storage failure looks like waste: ruined vaccine batches, spoiled produce, rejected shipments. But that’s just the beginning.

Let’s look at food manufacturing as an example.

Globally, the Food and Agriculture Organization (FAO) estimates that cold chain failures contribute to 526 million tons of food loss each year — roughly 12% of all food produced. That loss carries an economic cost nearing $1 trillion annually once you include disposal, logistics, compliance breaches and opportunity cost.

Because it’s also:

- Emergency freight charges to rescue shipments or reroute at short notice

- Insurance claims, which are often denied due to incomplete documentation

- Regulatory penalties or forced product withdrawals

- Long-term reputational damage with key customers and end-users

- Legal liability, especially for patient safety in healthcare settings

One temperature drift can ripple across departments and disrupt operations for weeks.

Why cold storage breakdowns still happen

If the risks are so well understood, why do breakdowns still occur — and so frequently?

The short answer: fragility, fragmentation and false confidence.

- Ageing infrastructure

Many cold chain systems still rely on outdated units, ageing compressors, or legacy controls. A failing thermostat can create a multi-million-pound problem if redundancy isn’t built in. - Siloed accountability

Ops oversee the units. QA checks compliance. IT handles data and legal manages risk. But no one owns resilience end to end. That creates gaps no one spots — until it’s too late. - Manual processes and monitoring

Clipboards, spreadsheets and human checks leave room for error. They also create lag. By the time someone notices a deviation, product is already compromised. - Compliance complacency

Passing an audit doesn’t mean you’re resilient. Routine checks don’t expose latent failures, degraded equipment or untested contingency plans. Many businesses are one power cut or missed alarm away from a crisis.

What a single temperature excursion really costs

Picture this scenario: a pharmaceutical firm is transporting a high-value batch of antibody therapies when a fault causes the temperature to climb to 15°C. By the time an engineer intervenes, two hours have passed, and the prolonged breach has triggered a full product recall under MHRA guidelines.

The nightmare begins to unfold:

- First, product loss: the units are a total write-off with a product value of some £900,000.

- Emergency logistics calls for Immediate dispatch of replacement stock, plus £65,000 spent on call-out fees, temporary cold storage and air freight from a backup supply hub.

- Regulatory action leads to a temporary suspension of wholesaler distribution authorization, stalling £4.2 million in expected revenue.

- Then, reputational rot sets in. Hospital trusts delay their procurement renewal processes, and a national healthcare group begins market review — opening the door to competitor bids.

- Finally, legal costs to manage the claim dispute and negotiate settlements with affected clients amounts to more than £40,000 and the insurance premium increases for the next renewal cycle.

The immediate visible cost to this hypothetical firm exceeds £5.2 million. But the long-tail commercial risk to them is far greater.

And, this is not the stuff of fiction; 60% of vaccine shipments experience a temperature excursion in transit.

in 2022, the NHS reported more than half of its vaccine wastage was directly linked to cold chain failures like faulty fridges, power outages and poor monitoring. The cost? Almost £3 million.

In the US, the US pharmaceutical industry loses roughly $35 billion every year because of temperature-controlled-logistics failures.

Passing the audit isn’t enough

Regulatory frameworks such as EU GDP, HACCP, FDA CFR Part 11 and EMA Annex 1 require strict control of temperature-sensitive goods.

Routine audits are in place to simply test readiness. But, once a cold storage failure takes place, the spot tests are over. You can expect to have to deliver:

- 100% audit trails

- Proof of alarm history and response times

- Staff training records and SOPs

- Third-party service contracts and equipment validation logs

- Full communication trails between departments

Without integrated digital logs and real-time monitoring, many businesses struggle to demonstrate compliance under scrutiny. And the cost of falling short? A temporary suspension can wipe out an entire quarter’s revenue — while competitors take your place on the shelf.

Trust is built slowly — and lost instantly

In an age of 24/7 news and instant online posts to millions of people, one cold chain failure can become a brand crisis overnight. The cost of cold storage failure is not just seeing profits crumble but the swift erasure of consumer trust.

- 40% of US adults have little to no confidence in the US federal government’s ability to ensure the safety of the US food supply.

- 54% of US consumers say they would stop buying from a brand after a single product safety incident.

- 83% of consumers won’t do business with brands they don’t trust.

Without trust, you lose repeat business, negotiating power and long-term contracts. And once it’s gone, it’s incredibly hard (and expensive) to win back.

Five board-level safeguards that pay for themselves

The most resilient companies don’t just plan for the worst — they invest in systems that prevent it. Here’s what that looks like in practice:

- Redundant equipment

Dual compressors. Auto-switch power supplies. Condition-based maintenance. These upgrades prevent a £50 part failure from becoming a £500,000 disaster. - Real-time monitoring

Integrated IoT sensors and cloud platforms provide 24/7 visibility. Predictive analytics flag anomalies before thresholds are breached — so you can act before product is compromised. - Contingency logistics planning

Pre-approved alternative routes, third-party reefer capacity and escalation SLAs reduce chaos during disruption. A “kill switch” approach allows Ops or QA to act decisively. - Quarterly incident drills

Simulated response scenarios across Operations, QA, Legal, Communications and Finance stress-test your systems — and expose gaps before regulators do. - Immutable digital audit trails

Automatically generated logs — complete with timestamps, sensor data, user actions and alarm resolutions — are a lifesaver during audits, claims or investigations.

ArcticStore case: resilience that earns trust

Many pharmaceutical companies rely on Titan Containers’ integrated SmartArctic monitoring. If power to a unit was to unexpectedly fail, SmartArctic sends an alert—even when internal temperatures are still within range.

In such a scenario, if a customer’s own system only monitored temperature thresholds, then no alarm would be triggered, and the issue would have gone unnoticed until it was too late.

A safeguard like SmartArtic monitoring speaks for itself:

- Zero product spoilage

- No disruption to operations

- Risk exposure significantly reduced

By monitoring both power and performance, SmartArctic will have helped turn a near miss into a valuable win for cold chain integrity.

Final word: cold storage integrity is brand integrity

If cold storage is mission-critical, then resilience is a board-level concern.

Staying reactive isn’t safe — it’s expensive. Therefore, investing in transparency, monitoring and preparedness isn’t just about mitigating risk — it actively protects revenue, accelerates recovery and strengthens competitive positioning.

In short, it pays for itself.

Take the next step — talk to our experts.

See how the right cold storage strategy can strengthen your operations and reduce costs.

Read next:

See more UK news and blogs

A reefer container is a powered, temperature-controlled container designed to store or transport chilled and frozen goods. This guide explains how reefer containers work, the different types available, and when they’re the right solution for cold storage needs.

Storage containers and shipping containers are often confused. This quick guide explains the key differences, standards, and what you need to know before renting or buying.

Revolutionary two-storey design, modular flexibility, and huge storage capacity – the Arctic MegaStore redefines cold storage efficiency.